Centrifugal Sifter For Our Flour

What is the Centrifugal Sifter For Our Flour?

Centrifugal Sifter For Our Flour, also known as a cyclone sifter, is used to grade and purify ground flour, ensuring uniform flour particles and free of impurities such as fine bran and insect eggs.

The main body of the flour centrifugal sifter is constructed of food-grade 304 stainless steel, which prevents metal contamination, is corrosion-resistant, and easy to clean, meeting food processing hygiene requirements. It can achieve 80-500 mesh screening, suitable for the production of premium, first-grade, second-grade, and standard flour. A single unit can produce 1-5 tons per hour, meeting the continuous production needs of flour mills.

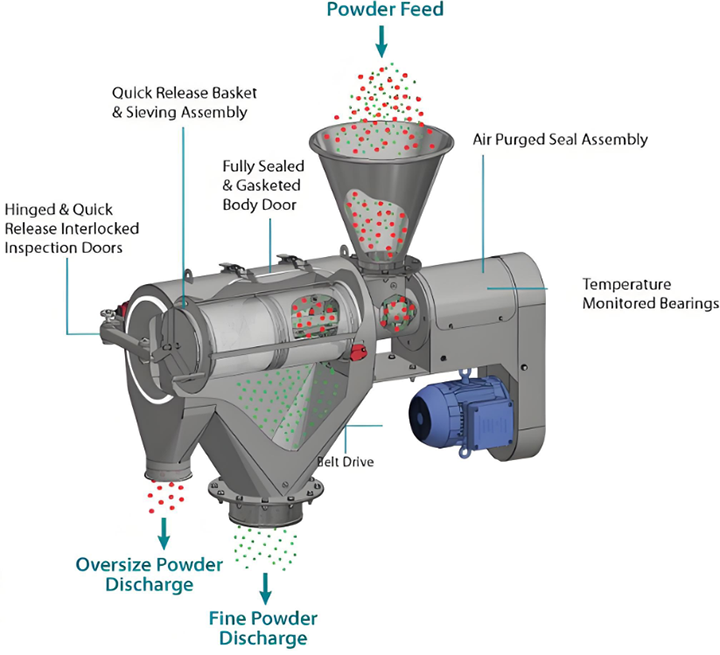

How the Centrifugal Sifter For Our Flour Works

The Centrifugal Sifter For Our Flour operates on the principle of centrifugal force-driven separation. When flour enters the machine from the feed inlet, it first encounters a high-speed rotating disc. Driven by a motor at 1000-1500 rpm, this disc generates a powerful centrifugal force, evenly distributing the flour onto the surrounding screens. Fine particles meeting the required particle size quickly pass through the screens under the centrifugal force and fall into the finished product chamber below. Coarse impurities such as unground bran and flour lumps are intercepted by the screens and, as they vibrate slightly, are pushed toward the coarse material outlet, completing the sieving and separation of the flour.

Centrifugal Sifter For Our Flour Specifications

| Model | Material | Power | Application |

| WQS18-65 | Q235A | 2.2KW | Screening below 500 mesh |

| SUW304 | |||

| WQS30-100 | Q235A | 4KW | |

| SUW304 | |||

| WQS50-130 | Q235A | 5.5KW | |

| SUW304 |

What are the advantages of the Centrifugal Sifter For Our Flour?

The Centrifugal Sifter for Our Flour offers high screening efficiency. Centrifugal force promotes full contact between flour and the screen, shortening material retention time and increasing efficiency by over 30% compared to traditional equipment. The flour centrifugal sifter offers stable screening accuracy, with a high-precision screen with uniform aperture. Combined with the directional force of centrifugal force, this prevents flour accumulation and ensures consistent particle size in the finished flour. Operating costs are low, thanks to its dynamically balanced design, which minimizes vibration and noise, reducing component wear and extending service life. The 304 stainless steel construction is easy to clean and reduces maintenance costs. Furthermore, the Centrifugal Sifter for Our Flour offers high safety, with food-grade materials and a sealed design to prevent moisture and external contamination during sieving, ensuring food hygiene and safety.

Centrifugal Sifter For Our Flour Video Showcase

What is the difference between the Centrifugal Sifter for Our Flour and a vibrating screen?

The Centrifugal Sifter for Our Flour differs from a vibrating screen. In terms of their operating principle, a centrifugal sifter relies on the centrifugal force generated by a feeding disc to drive screening, actively pushing the material toward the screen. A vibrating screen, on the other hand, uses the vibration of an eccentric block to drive the screen, relying on the material's gravity and inertia for screening. In terms of efficiency and precision, centrifugal sifters, due to their stronger centrifugal force, are less likely to clog the screen when processing lightweight materials like flour, resulting in superior efficiency and precision. Vibrating screens are prone to incomplete screening due to flour accumulation, resulting in large fluctuations in accuracy. Furthermore, centrifugal sifters operate at lower noise levels and consume less energy than vibrating screens, making them more suitable for the continuous, low-noise production environment of flour mills.

What is the Centrifugal Sifter For Our Flour used for?

The Centrifugal Sifter For Our Flour can be used to grade refined and standard flour, removing impurities such as bran and stones from the flour to improve flour quality. It can also be used for pre-shipment inspection of flour to ensure that the finished product particle size meets specifications. In addition to flour, it is also suitable for screening grain powders such as starch, rice flour, and soy flour, as well as removing impurities from food powders such as milk powder and protein powder. In the pharmaceutical and chemical industries, it can also screen pharmaceutical excipients and fine chemical powders that meet particle size requirements. Simply replace the corresponding screen and follow the cleaning process.

As a flour processing device, the Centrifugal Sifter For Our Flour, with its rapid screening capabilities, operational efficiency, and safe material design, ensures improved flour quality. Its differentiated advantages over vibrating screens also make it more suitable for processing lightweight powders like flour. Whether used for flour grading, impurity removal, or cross-industry powder screening, it plays a vital role, providing strong support for refined and automated production in the powder processing industry. It is a crucial piece of equipment for reducing costs, increasing efficiency, and ensuring product quality for food processing companies.

-

Battery Anode Materials Vibrating Sieve

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

-

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

-

Remove small stones, sand or clay particles, leaves, dust and other ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve price

Standard test sieve price usually ranges from US$20 to US$300, depending on the size, material and accuracy level...

-

Vibro Sifter Flour

The Vibro Sifter Flour uses a motor-driven eccentric weight to generate three-dimensional vibration...

-

Vibro Sifter Baking Soda

Vibro Sifter Baking Soda is a process or equipment that uses a vibrating screen to sieve, grade, or filter baking soda...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.